Services

Unparalleled Manufacturer of Circuit Board Assemblies

At Electronic Specialties of Connecticut, Inc., we offer the highest quality of craftsmanship in the business. We take pride in driving the entire electronic industry forward while finding the newest technology to incorporate into our services.

Our 14,500 square-foot, climate-controlled facility has an extensive stock room for housing both consignment and turnkey projects. We also have material requirements planning (MRP) system, allowing us to take supplies from various vendors and build the product to your exact specifications.

The various pcb assemblies we can build for you

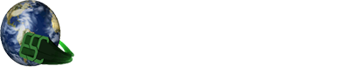

Through-Hole Assembly

ESC began building thru hole assemblies in 1981. Whether it's pure thru hole or mixed technology our years of experience, component management system and dedication to quality make us your choice for thru hole assembly.

Our IPC-A-610 and J-STD-001 certifications along with our aqueous cleaning line ensure a quality product and on time delivery. Both ROHS and non ROHS assemblies are supported throughout the process.

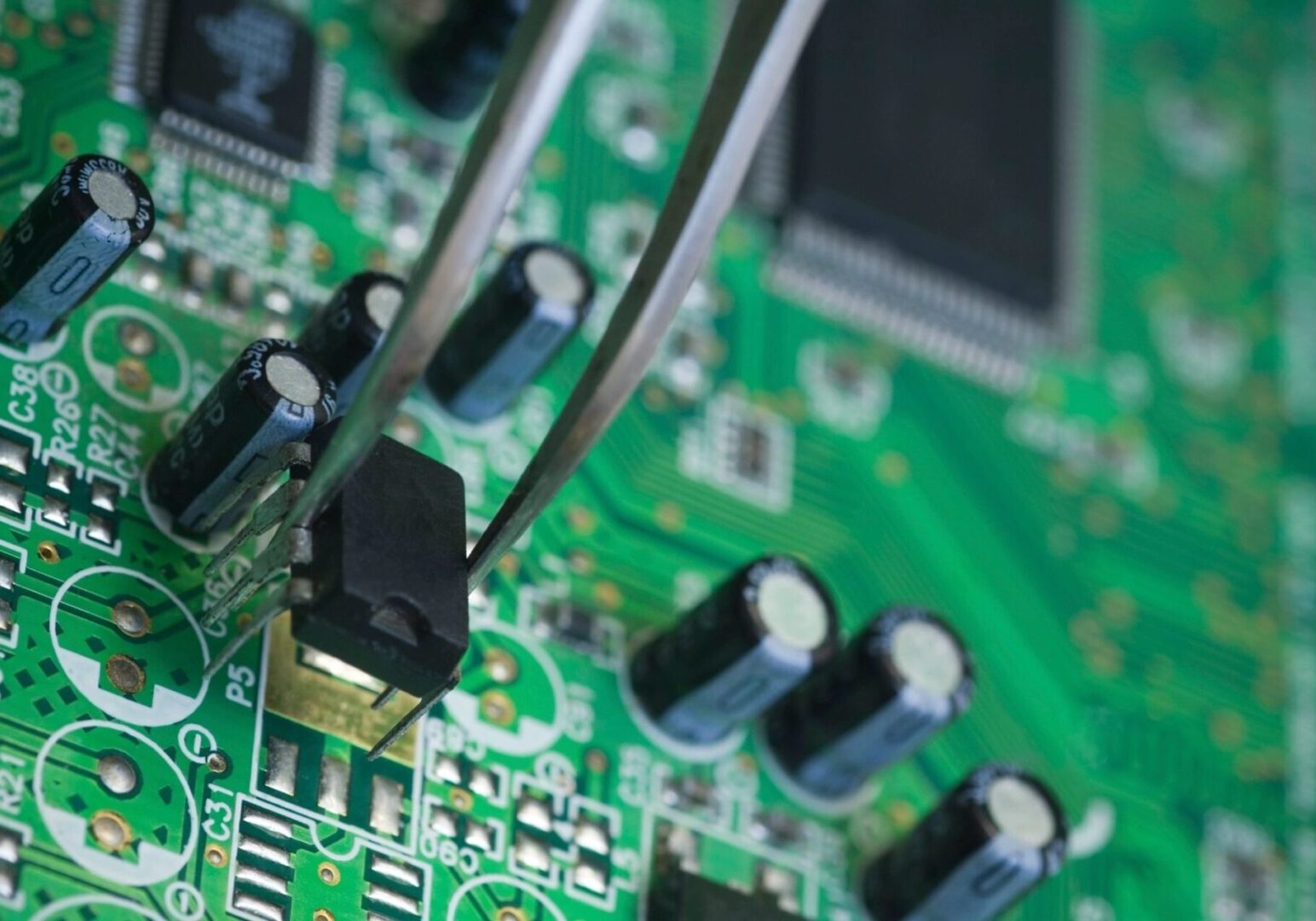

Surface-Mount PCB Assembly

ESC's surfacemount line can handle anything from small prototype runs to full production. Our high-speed Juki line coupled with our Speedline MPM Momemtum elite printer and our Electrovert Omnimax oven can place up to 60,000 components per hour. Our highly trained operators along with our component management system allow us to move quickly from job to the next.

All surfacemount assemblies are AOI inspected to ensure quality and dependability.

Other services

Testing: Both AOI and full functional testing along with our highly trained inspectors ensure quality and reliability.

Materials Management: At ESC we work with consigned material, full turnkey or a combination of both. Our materials management system ensures the availability of the components required to build your product.

Value Added and Unit Assembly: Whether it's the addition of cable assemblies or the integration of sheet metal or plastic, ESC has the personneel and facility to assemble and test your product.

Design Services: From circuit design, layout or full product design, ESC has the team to get it done.

What We Offer

- Wave Soldering, ROHS & NON-ROHS

- Aqueous Cleaning

- Circuit Modification

- Harnessing

- Packaging

- Testing

- Box Build Unit Assembly

- Prototyping

- Full Assembly Production

Our Equipment

- High Speed Juki Pick and Place Line

- Speedline OmniMax With Ten Zones Reflow Oven

- Full Aqueous Cleaning Line

- Automated Optical Inspection (AOI)

- Schleuniger Cut and Strip

- HEPCO Prep Machine

- Mantis and Lynx Inspection Equipment